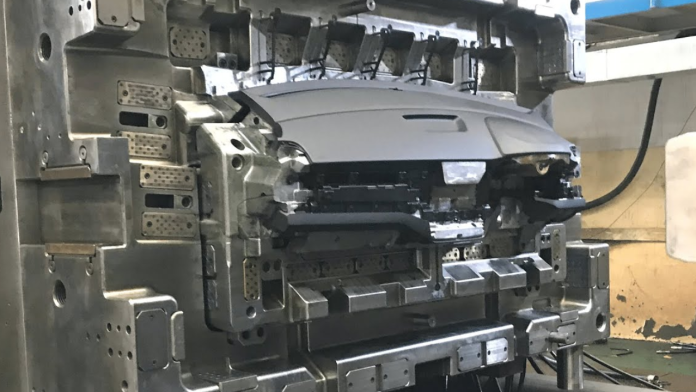

Making molds is an unassuming yet essential skill that serves as the silent mastermind behind the mass production of several items that are a part of our daily lives. In this laborious procedure, molds are made to shape and form materials ranging from plastic to metal, frequently using strong materials like metal or silicone as the base.

A complex ballet of artistry and accuracy is at the core of mold making. The thorough design phase, frequently aided by state-of-the-art Computer-Aided Design (CAD) software, begins the process. To convert complex product drawings into three-dimensional molds that will produce identical reproductions, engineers and artisans work together.

What Are The Main Components Used To Make Molds?

Material selection is an important consideration in the complex realm of mold building because it affects the end product’s strength, accuracy, and effectiveness. Molds are frequently made of strong, long-lasting materials like metals; the most popular options are steel and aluminum.

These materials ensure durability and repeatability by providing the structural integrity required to survive the severe conditions of the molding process. Flexible materials like silicone are best suited for more complex or sensitive applications. For a wide variety of molding applications, silicone molds are preferred because of their propensity for capturing minute details and complex geometries.

The type of material to be molded, the complexity of the design, and the unique requirements of the manufacturing process all play a role in the deft choice of materials used in mold production. As technology develops, new metals and composite materials are being researched to push the limits of mold production, providing accuracy and versatility across many industries.

Methods Are Applied When Creating Molds

Various machining processes are used during the mold-making process to precisely shape and form the chosen material for the mold design. Several important machining methods for creating molds are listed below:

Milling:

Using a spinning cutter, milling is a subtractive manufacturing process that shapes a workpiece by removing material from it. For accuracy and efficiency, CNC (Computer Numerical Control) milling machines are frequently utilized in the manufacture of molds. Metals and plastics can both be used in the milling process, which is flexible and capable of handling a variety of materials. It is used to produce the general curves and shape of the mold cavity and core.

Turning:

A workpiece is rotated during the machining process of turning, which uses a cutting tool to produce cylindrical shapes. Turning is frequently employed in the mold-making process to obtain concentricity or to produce cylindrical features. It is useful for producing features like inserts and other cylindrical parts, as well as mold cores.

Machining by electrical discharge (EDM):

With the help of electrical discharges between an electrode and the workpiece, the material is removed during the unconventional machining process known as EDM. It works especially well for complicated and elaborate shapes. It is frequently used to produce complex shapes, exquisite finishes, and delicate features in molds.

Drilling & Electrical Discharge Machining

By utilizing a revolving cutting tool, drilling entails making holes in a workpiece. Drilling is used in the mold-making process to make holes for features like cooling channels and ejector pins.

Necessary for sculpting apertures and details inside the mold. Using a thin wire as an electrode, wire EDM slices through the workpiece. It is incredibly accurate and ideal for producing intricate shapes and contours. Carving complicated contours and shapes in hardened materials is especially useful for this.

Laser Machining & High-Speed Machining

A concentrated laser beam is used in laser machining to remove material. In the creation of molds, it is frequently utilized for precise cutting and engraving. Applied for cutting, engraving, and fine detail creation in various mold components. High spindle and cutting speeds are used in HSM to accelerate material removal rates. The efficiency of producing molds can be increased using this method. It is used to swiftly remove material from molds and create smooth surfaces.

Final Talk

Mold making is the unassuming conductor in the symphony of industrial production, coordinating accuracy with imagination to produce a wide range of goods that characterize contemporary life. The art and science of mold manufacturing shape our material world with a refinement that is both amazing and necessary, from the svelte lines of a smartphone to the delicate components of medical equipment.