CNC machines are an amazing tool for producing a wide range of items, especially in the field of large CNC machining, but they have certain size restrictions of their own. A notably large machine is unlikely to be owned by the typical machine shop or enthusiast because these kinds of tools are often impracticable.

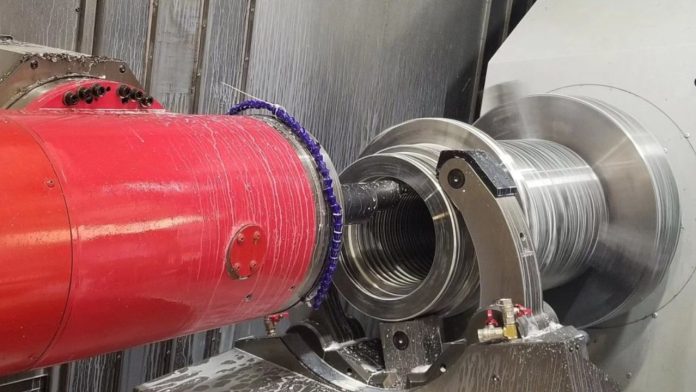

Large CNC machining is a type of CNC machining used in manufacturing to produce larger, more complex parts and components. Large CNC machining centers are utilized in many different industries, such as construction, automotive, and aerospace, and can handle workpieces ranging in size from a few inches to several feet.

Large CNC machines can produce intricate features and geometries on a bigger scale with the same degree of accuracy and precision as their smaller counterparts. To operate these machines, certain tools and knowledge are frequently needed. You can visit now this article for more data about large-part machining.

Considerations for Large Part Machining

Large-part machining presents unique challenges that require careful planning and consideration to ensure successful and efficient production. Manufacturing large components demands meticulous attention to detail, advanced machinery, and a well-thought-out strategy. Here are some essential considerations for planning issues in large-part machining:

Overall Part Size

The other major limitation that comes with such a task is overall size. If it is too large for your enclosure, it needs to be done in sections. Similar to this, a lot of machines have a weight limit that applies to both the component and all fixtures, and height can make or break a machine. It might not be worth it at all if the part is too tall or heavy to fit under the machine.

Limited Types of Large Machining Tools

The fact that there are so few machine tools available specifically for developing huge parts can also be a challenge. Many manufacturers have entered this industry at the expense of any tools that specialize in large parts because the majority of machines are made for smaller lot sizes.

This can happen even with huge machines, as many machine shops require operator attendance to manually finish the product, which can take some time.

Machine Capacity and Capability

Large-part machining necessitates specialized equipment with substantial capacities and capabilities. Consider the size, power, and precision of the machining tools, including CNC milling machines, lathes, and multi-axis machining centers. Evaluate whether the existing machinery can handle the dimensions and weight of the large parts or if investing in larger or more powerful equipment is necessary. Proper maintenance and calibration of the machines are essential to ensure accurate and reliable machining of large components.

Fixture and Tooling Design

Designing appropriate fixtures and tooling is crucial for securing large parts during machining. Custom fixtures must provide stable support and minimize vibrations to prevent inaccuracies in the machined surfaces. Additionally, consider the accessibility of the cutting tools to all areas of the large part to ensure uniformity in machining. Collaborating with tooling experts and conducting thorough testing are essential to determine the optimal tooling solutions for specific materials and machining operations.

Summary

Large CNC machining is the process of producing larger, more complex parts and components. Large parts require careful planning and consideration for various configurations, the size of the part overall, the limited number of machine tools available, precision, the design phase, and other factors while machining. With the correct machining know-how and extra preparation, massive items can be machined. CNC machines can produce intricate features and geometries on a bigger scale with the same accuracy and precision as their smaller counterparts.