Thermal management techniques help design high-performance technological products. Today, cold plates are widely used in limited space applications, but high power output is in demand. Cold plates possess desirable characteristics in a water cooled heat sink that make them common. They have a higher thermal conductivity and compact design. If you want to know more about how a liquid cold plate works, keep reading the article.

What is a liquid cold plate?

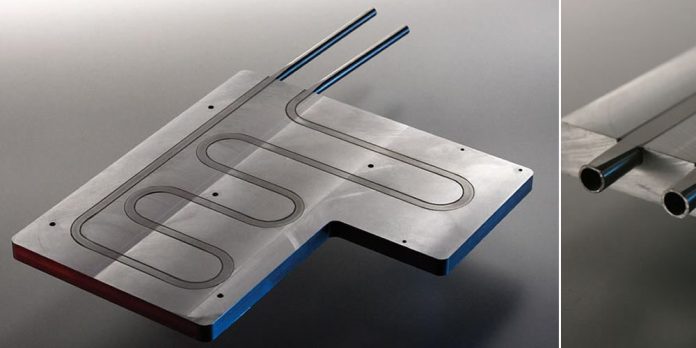

Liquid cold plates are designed to transfer heat from points with higher heat loads to the cooling fluids within the system. The cooling fluids flow to the heat exchanger, which dissipates heat into the secondary cooling fluid. By doing so, the cold plates help cool electronic appliances. Manufacturers use milled parts to make liquid cold plates and weld them by friction stir welding. The performance of the plates will impact the effectiveness of the cooling system and the electronic devices but, to determine the ideal cold plate solution for any given system, designers analyze the appliance and its requirements. Reputable manufacturers can improve on the design you had in mind and offer you a high-efficiency and affordable liquid cold plate. Additionally, they can custom design cold plates that meet your specific needs.

Applications of a liquid cold plate

Today, most electronic appliances need liquid cooling to attain the required temperatures of system components. Liquid cold plates are vital components of the cooling systems of various devices. These include:

- Fuel cells

- Motor drives

- Avionics

- Medical equipment

Working of a liquid cold plate

A liquid cold plate is made from metal and provides localized cooling to electronic equipment. The cold plates contain flow paths that allow the flow of heat-transfer liquid. The flow paths enable the cold plates to absorb large amounts of heat and transfer it effectively. The liquid cold plate absorbs electrical waste heat and dissipates it through the machined flow paths. There are different ways heat flows from the devices to the coolant. Heat flows by conduction from the component to the thermal interface, the metal and the metal tubing. Then convection facilitates heat flow from the fluid path’s internal surface into the coolant flowing in the cooling system. Manufacturers machine flow paths of liquid cold plates into varying shapes and sizes. The heat transfer coefficient of a liquid cold plate depends on several factors like the flow paths’ surface area and cooling liquid used. What’s more, the cooling fluid’s cold plate material and flow rate can also affect the plate’s heat transfer coefficient.

Selecting the proper fluid

Liquid cooling systems are more effective and allow high-performance cooling. These systems take up less space as they only require tubing, a pump, plates, and a heat exchanger. That is why liquid cold plates have replaced fans and heat sinks. To ensure optimum performance of the liquid cold plates, you need to choose the right coolant. A wrong working fluid could cause clogging and poor heat transfer. On the contrary, the right coolant will have the proper thermal stability, low freezing point, and high thermal conductivity. The commonly used coolants are water, dielectric fluids, deionized water, and inhibited glycol.

Conclusion

Liquid cold plates are popular cooling options in most electronics because of their benefits. Knowing how they work and the right working fluids will ensure you optimize their performance.